Digital microscopes are useful systems in quality control environments, including the medical device manufacturing industry. In a high production setting, it is important to establish quick automated pass/fail protocols to maintain quality standards. YSC Technologies’ digital USB microscopes with automated measurement software are excellent solutions to this need. We explore these benefits through the bone screws inspection application.

Quick Pass/Fail Analysis and Automated Measurement

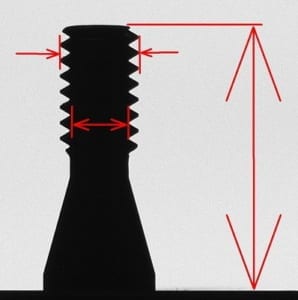

Our digital microscopes offer measurement features that allow live images of the bone screws to be compared against their CAD data. The CAD drawing is overlayed on top of the live image for automated pass/fail checks, eliminating operator subjectivity. The software can automatically measure the bone screw’s thread diameters and other characteristics with high accuracy. Measurement data, statistics and images can be saved for later in-depth analysis of results.

Extended Depth of Focus on Digital Microscopes

Additionally, our digital USB microscopes have extended depth of focus; every feature on the bone screw will remain in focus, including the helix angles. This eliminates the need to constantly refocus the live image to inspect features on different planes and also minimizes potential operator error through manual adjustment.

Video Measurement Digital Microscopes to Meet Versatile Demands

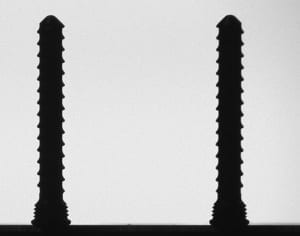

Video measurement digital microscopes ensure quality standards are met through inspection and measurement of manufactured components.

Systems like the MX8000 digital microscope automate calibration and edge detection to save operator’s time during the measurement and pass/fail checking process. Our Omni-Core microscope streamlines the process even further with auto focus capabilities and removes manual focus adjustments from procedure.

For applications requiring larger measurements while maintaining high accuracy, XYZ measurement systems are also available to help the efficiency of quality control protocols by automating the measurement and inspection process as much as possible.