In the electronics industry, quality control (QC) and quality assurance (QA) processes ensure products meet proper quality standards prior to their release into the consumer market. Because electronic components are often quite small in size, digital microscopes substantially improve efficiency and accuracy of inspections in comparison to their traditional optical predecessors. Digital microscopes’ digital features also present the opportunity to document and thoroughly collect data for further analysis and reporting, which can be especially helpful for training and process evaluation.

Defect Detection of Electronic Components

During post-production, electronic inspectors are assigned to visually verify a product has no unacceptable defects (i.e. surface cracks, blemishes, etc). Specifically for PCB manufacturers, inspectors must also check to ensure wires on the bare board, solder paste, and placements of components have been applied correctly. Optical microscopes are often used during these processes due to how minuscule the defects or components are. However, because field of view is small when viewing through eyepieces, it may take more time for the inspector to locate focal points and complete their inspections.

On a digital microscope, you don’t need to be hunched over to look through eyepieces and instead, can sit comfortably in an upright position to view your inspection on a larger monitor screen. Digital microscopes also provide a larger field of view in HD 1080p or higher resolution, and the ability to zoom in for quick inspections in excellent live image quality. Moreover, the monitor screen gives the option for multiple people to simultaneously viewing the same component, minimizing individual user subjectivity and error through discussion among colleagues.

Optical microscopes are also limited by their structural anatomy. Digital microscopes can be configured with a variety of stands and focus mounts, and can even come in a handheld portable form. This supports tilting the microscope at an angle to properly view electronic components that are otherwise hard to inspect on a traditional microscope. Better ergonomics and easier usability promotes operators’ efficiency and accuracy during their inspections.

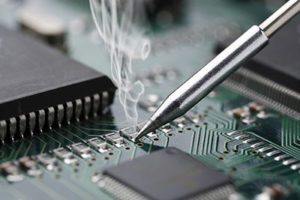

Repair and Reworking PCB’s Electronic Components

In-production and post-production aren’t the only instances in the electronic component manufacturing process that require inspection under the digital microscope. If a component has failed a quality control inspection, the points of failure are evaluated before returning to the operator for repair and rework the product to meet quality standards.

Because of the tiny scale of the components, especially those found in smart phones and tablets, traditional tools like magnification lamps or optical microscopes may not be sufficient with their limited field of view to do proper repair/rework. The digital microscope displays the live image onto a monitor screen so that the operator can view what they’re working on directly on-screen instead of eyepieces. The microscope can also be configured with a taller stand to accommodate for the required clearance needed for the operator to use their rework tools under the scope while retaining focus on the component.

Documentation and Data Collection

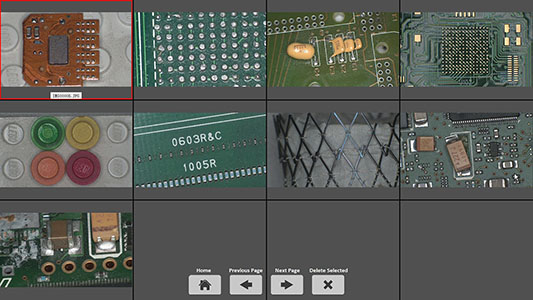

Quality assurance and pass-fail analyses may require documentation to detail why a component did not pass inspection. These notes can be reviewed in the future for further analysis or training purposes. Digital microscopes can capture and save images onto an internal SD card, USB drive, or directly to a PC, so that visual references can be added to reports to support the observations specified. Annotations can even be saved directly onto the images to easily recall why the image was taken in the first place.

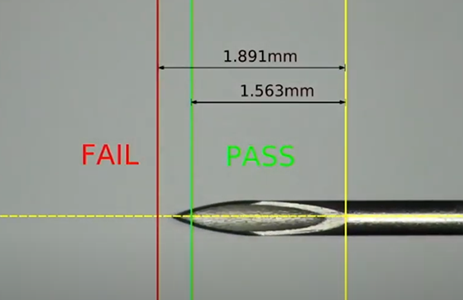

Additionally, many of our digital microscopes have built-in or PC-side measurement software, which are useful in verifying the decision to pass or fail a particular inspection. These measurement tools can also help gather data to determine what percentage of the manufactured electronic components are failing the inspections, and if manufacturing procedures need to be improved to decrease the percentage of failures.

The digital microscope measurements can be done either on the live imaging or captured still images. Up to 10 calibrations can be stored in the measurement software for faster recall time and eliminates the need to recalibrate every time magnification and working distances are changed. Measurement data can also be exported in TXT or EXCEL format for further study and reporting purposes.

Image Processing and Measurement Software Features

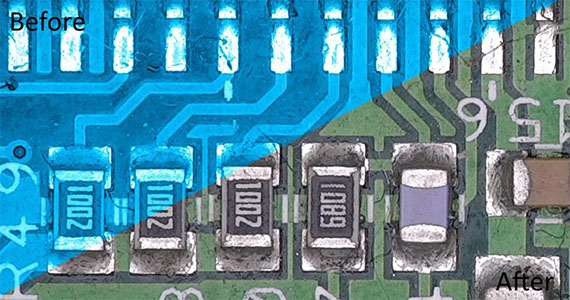

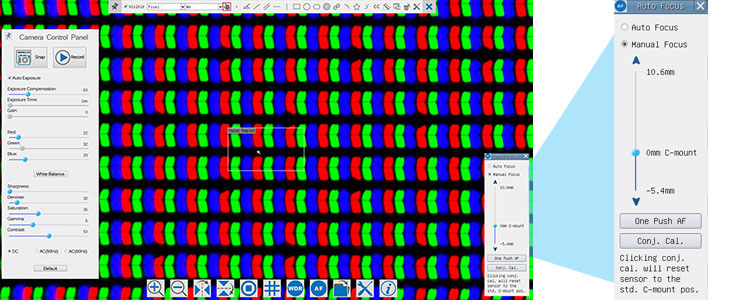

On an optical microscope, your electronic inspection image conditions are limited to the quality of your optical lenses system as well as the lighting used with the microscope. Much like the consumer digital camera, the digital microscope has different camera setting adjustments to help you correct and produce optimal imaging. These settings include, but aren’t limited to: exposure adjustment, white balance, color temperature adjustments, brightness, saturation, etc.

The digital microscopes’ imaging software supports image comparison between the live imaging and a saved still image. This is usually executed via side by side comparison, in which the still image takes up half the screen space while the live image takes up the other half for effortless comparison against a “golden standard” image. One of our more advanced digital microscopes, the Omni-Core auto focus system, allows the ratio of the side-by-side live and still image comparison windows to be adjusted according to your needs. Omni-Core also has an overlay comparison feature, in which the “gold” master image is overlayed and flashed against the live image so you can easily spot the differences.

Most of our digital microscopes include extended depth of focus and image stitching features in the image processing software to create one superior image. Image stitching allows multiple still images to be pieced together to form one larger, combined image. This can be useful if your application requires high quality imaging and a large field of view (ex. if you were to capture the entire PCB board).

When inspecting small PCB components, the high magnification required on the digital microscope may result in a very shallow depth of field. However, the extended depth of focus features is an excellent workaround solution to this issue: it stacks multiple captured images (taken from various focal points) so that all components within that area, despite differing planes, will be in complete focus. Not even an optical microscope can achieve this sort of depth of field!

Advanced Digital Features Beneficial for Electronic Inspection

When it comes to digital features, the possibilities can be endless, especially if you have the budget for it. While electronics inspection may not need all the bells and whistles out there, some of these advanced features can still make the process that much more productive.

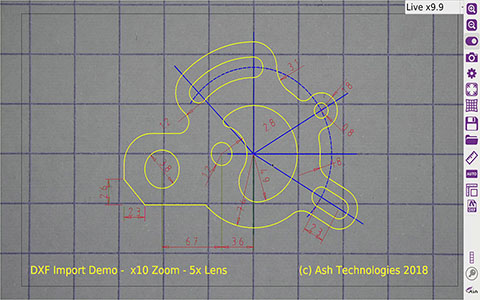

DXF Files Importing & On Screen Reticule Graticules

Our Omni-Core and Inspex II auto focus systems both offer the option to import DXF files, which can then be overlayed onto the live feed for quick comparison and pass-fail analysis. The DXF files can also be edited and annotated directly from the microscope systems, which can drastically reduce time taken to create graticules.

You also have the option to create your own on-screen reticule graticules through the measurement app, which can then be saved to the camera’s internal memory for future use. Upon being recalled, the graticule will appear as an overlay, and automatically zooms to the appropriate zoom level the graticule was saved in to ensure accurate measurements. This feature enables straightforward pass/fail analysis ideal for high volume inspection requirements.

Auto Focus for Minimal System Adjustments

Having a digital microscope with auto focus capabilities could save you time on your inspections because your live image could be brought into focus with a click of the mouse or button. Instead of having to manually focus your image every time you adjust settings or change out your sample, your hands will now be free of move your circuit board/part around or even do some soldering and rework under the scope, all without losing focus. Check out our Manual Focus vs Auto Focus page to help you decide if getting an auto focus digital microscope is right for your needs!

YSC Recommendations for Electronics Application

Our manual focus HD 1080p digital microscope HD801 is a popular option for PCB inspection and rework applications. With a long working distance range of 4.5” to 12”, it provides ample clearance under the scope to use tools for repairs and rework while still maintaining a clear image of the area of focus. The system also has measurement tools and can save images directly an SD card without requiring computer connection.

If your operators are used to doing their inspections and repairs on a traditional microscope with eyepieces, the HD8TR trinocular digital microscope may be a good hybrid to consider. The HD8TR is configured with a digital microscope camera mounted onto its trinocular port, so you get all the benefits and tools of digital microscopy while still providing the option to view through eyepieces for more detailed inspections.

If you have a healthy budget and are intrigued by the software potentials of a digital microscope, you can consider the Omni-Core auto focus digital microscope. Designed with customization in mind, the Omni-Core offers high definition digital imaging and lets you choose which of their optional app features you’d like in order to maximize the efficiency of your inspection and repair process. These optional features include: 2D measurement and annotation, focus stacking, image overlay comparator, side by side comparison and on-screen reticule graticule.

For more information on choosing the right digital microscope for your electronic needs, contact us today!